New into the piping world? You are at the right place. You must be wondering, what types of flanges are there in piping. A pipe flange is basically used to connect these items; valves, pipes, pumps, and other necessary items in order to create a piping system. You might want to buy stainless steel flanges malaysia for your piping system. Usually, flanges are screwed or welded. They are used to ease the maintenance of the piping system and they are very easy to dismantle if there is a need to do so. There are many types of flanges that are commonly used in a piping system. These are some of them:

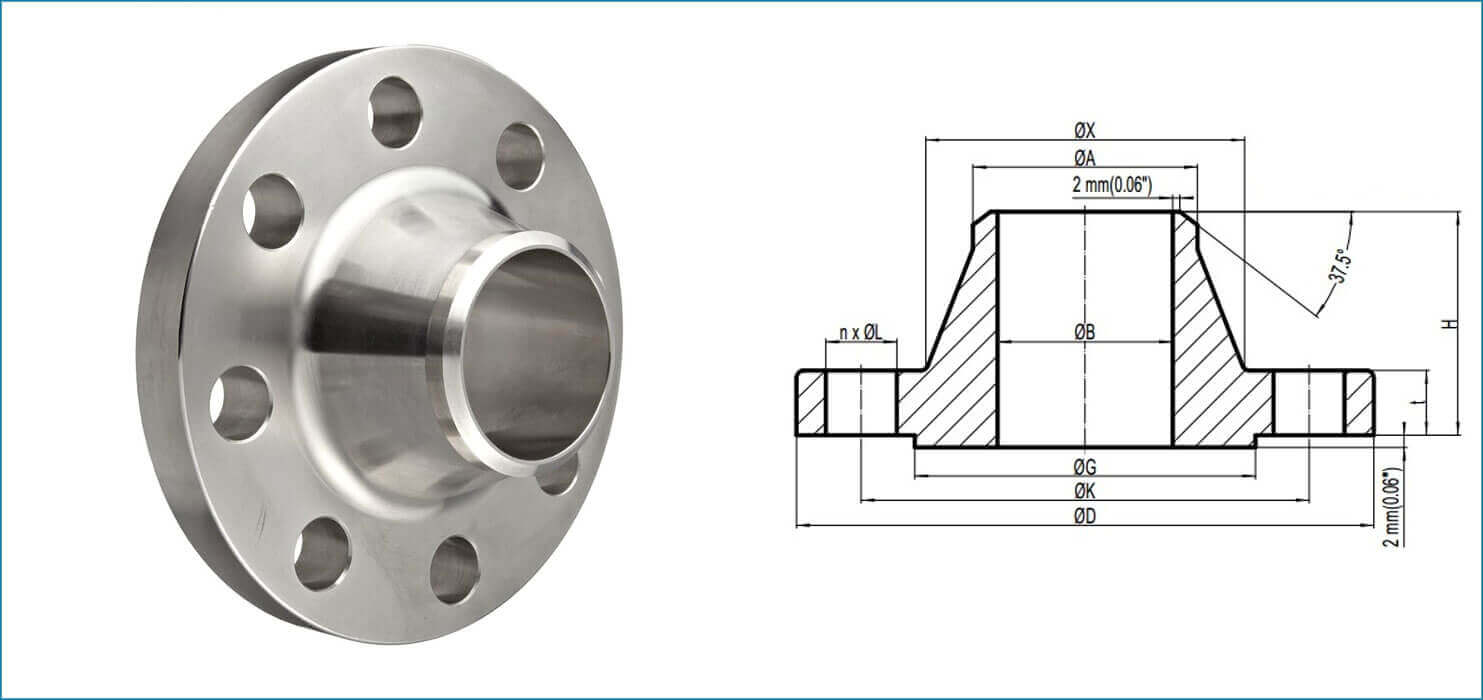

Weld neck flanges

This type of flange is usually easy to spot. Sometimes known as tapered hub flange or high-neck flange. It normally goes continuously depending on the structure’s thickness from a pipe or a fitting. Weld neck flanges are connected by a butt weld connection used to the equipment that would require a flanged joint. They are very suitable to be installed with pipelines that deal with both low and high temperatures. They are capable to withstand high pressure too, making them widely used in piping systems, especially in creating manholes and used for pressure vessels too.

Socket-weld flanges

The second type of flange on our list is the socket-weld flange or SW Flange. They are very suitable to be used with smaller pipe diameters, especially in both low-temperature and low-pressure situations. The inside of an SW Flange (Socket Weld Flange) has a shoulder that serves as a guide for setting the depth at which the pipe is welded to the flange.

Threaded flanges

Normally used for low-pressure systems, threaded flanges come with a tapered internal thread which allows the pipe to be screwed into. They are usually available in various sizes and the maximum is 4 inches. This type of flange is not suitable in high-temperature premises and locations such as welding and also in explosive areas such as the gas stations.

Blind flanges

Blind flanges are typically used to make a stop or seal a pipeline. Unlike other flanges, they don’t come with a center hole and fluids cannot pass through them. They have to cope with high mechanical stress which is caused by the system pressure. They enable easy access to the pipeline since they are easy to dismantle. This is one of the reasons why they are widely used especially as manholes.

Slip-on flanges

This type of flange is the most common out of all flanges, They are available in many sizes. Basically, a slip-on flange is a ring that is put over the end of a pipe. Two fillet welds, one inside and one outside the cavity of the flange, connect a slip-on flange to the pipe or fittings.

Lap joint flange

Lap joint flanges have a two-piece design that requires butt welding the stub end to the pipe or fitting and then using a backing flange to complete the flanged connection. Normally used in systems that work with small space and would need to be dismantled often. Just like other flanges mentioned before, they share the same common look or dimension, it’s just that they do not come with a raised face. They are quite similar to slip-on flanges but there are a few differences in terms of the intersection of the face, where the radius is different.